Transmission shafts or just shafts are used in virtually every piece of rotating machinery to transmit rotary motion and torque from one location to another part of machine. New Design of the Automobile Automatic Gearbox Providing Driving Simplification and Driver Fatigue Decrease December 2017 Transportation Research Procedia 20544-549.

12Shastri DRamamurthy Sand ParabPSTRATEGIES FOR This paper suggests selection of appropriate of plastic the AUTOMOBILE SELECTION SAE Technical-28-0055 P2008 simple gear design and development of gear by suitable doi.

. Design and static analysis of automobile. Types Of Automobile Gearbox Working of Sliding Mesh Gearbox. This combination of manual gearbox and CVT is designed in such a way that it provides the required gear ratio and satisfies our requirement for an All-Terrain Vehicle.

O In automotive applications the pump typically is connected to the flywheel of the engine The turbine is connected to the input shaft of the transmission. By providing a checklist and ensuring customer needs are considered a methodology directs design efforts in the most productive direction. Gearbox Design Machine Design- Interview Question and Answers.

Gear design is a highly complicated art. The first shaft of designed gearbox was designed to manufacture. It should help students not familiar with gearboxes lay out a reliable working design.

Small gear driving large gear Under Drive Under Drive happens when Carrier is the Output Under drive increases Torque decreases Speed Large Gear driving Smaller gear Overdrive Overdrive happens when the Carrier is the Input. Design of a manually operated automotive gearbox. Reality the theoretical power losses of the spur gear occur in various conditions in addition to mechanical losses and pump losses9 Designing a gear was the most technically challenging aspect of the design process.

Variable speed gear box Fluid Couplings Torque Converters for automotive applications. To better design a set of gears an example of two spur gears will be calculated step by step with the writing of the basic. What is gearbox or transmission.

Gearbox in automobile. DESIGN OF AN AUTOMOTIVE DIFFERENTIAL WITH REDUCTION RATIO GREATER THAN 6. At the very least the same setup could be used but.

The gear number 11 is pressed on the shaft. Types-pressure angle and under cutting base circle determination-forces and surface stresses. To we engage the 2nd gear we move the lever like in the last image and the gear selected fork will engage the collar in the 2 nd spur gear blue.

Between maximum and minimum values. Gearbox Design Layout only Gearbox Design Issues. Position of the fourth gear next to the final drive was possible to use the second shaft of the gearbox MQ200.

Machine Design Project Report Semester 1 20142015 Group 3B1 4 fDESIGN SPECIFICATIONS Motor. By using the given rotational speed of 1800 rpm input power of 10 horsepower gear ratio of 35 and an overload factor of 15 the rough dimensions of the gear and pinion were determined. Rotating Elements ie gears sprockets pulleys etc 3.

UNIT V CAMS CLUTCHES AND BRAKES 9 Cam Design. Gear box finds its application in Agitators conveyors crushers cranes elevators feeders small ball mills mixers cooling towers Extruders Packaging and. System Design 21 Powertrain layouts The previous powertrain design consisted of two Emrax 228 motors each with a chain drive single gear reduction to independently drive the rear wheels.

Introduction to Gear Design Introduction Albert Einstein once said. When the engine is running and the car is stopped the stator will lock on the One Way Clutch. While the transmission is in gear as engine speed increases torque is transferred from the engine to the input shaft by the motion of the fluid propelling the vehicle.

A part of the shaft is a wheel of parking pawl. To ensure capable processes this includes considering both process design considerations and established business requirements. This system was used as a baseline to which other designs were compared.

Constant mesh gear box - Speed reducer unit. The constant pressure to build less expensive quieter running lighter and more powerful machinery has resulted in a steady change in gear designs 3. Also facilitates change of direction of output shaft for reversing Automotive gearboxes are used to reduce load on the engine by manipulating torque and speed.

Study and Sectional View of Differential Gear- Mechanical Projects. Introduction and Purpose Provides speed and torque conversions because of the limitations of internal combustion engines. A design methodology also aids in training new manufacturing engineers.

There are no great advances in gear technology described. When the collar engages in the any spur gear there will be a transfer of rotation between spur and differential and now we have rotation in wells. With these major changed to the design the gearbox is still operating well and safely according to the theoretical calculations.

5 hp with 1800 rpm Capacity. It may be a gearbox a torque converter overdrive fluid drive or hydraulic drive. Locate and secure components in an appropriate manner and in their proper position.

Index TermsAll terrain vehicle bracking differential gear roll cage shaft steering system suspension transmission vechicle wheel. New Design of the Automobile Automatic Gearbox Providing Driving Simplification and Driver Fatigue Decrease. Things should be made as simple as possible but no simpler This book is an attempt to apply that principle to gear design by presenting information from a manufacturing point-of-view rather than a theoretical one.

And the same principle applies to the other gears. Each of the chapters will deal with a-specific problem which is encountered during the design phases and during operation. At present much is known about gear load-carrying capacity and many complicated processes for making gears are available.

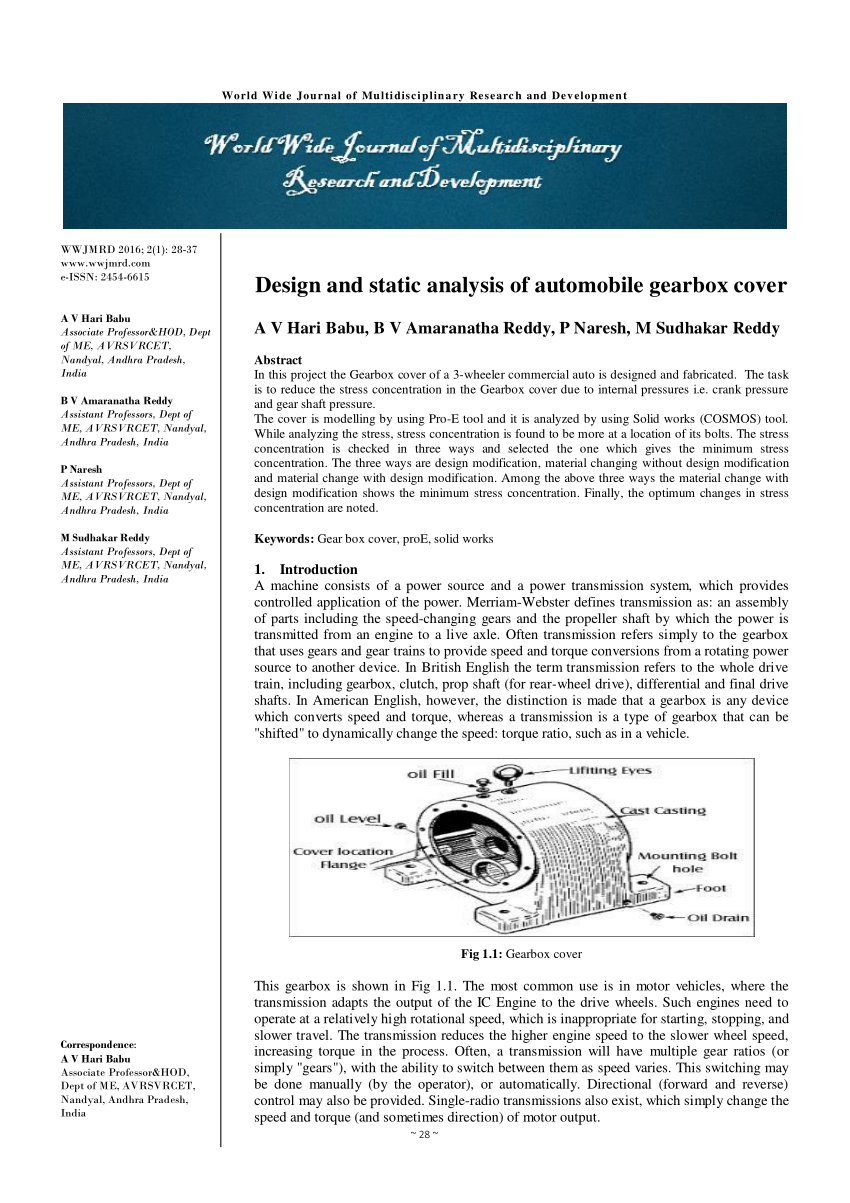

PDF In this project the Gearbox cover of a 3-wheeler commercial auto is designed and fabricated. The second shaft was adapted for design purposes before heat treatment. Volume 20 2017 Pages 544-549.

The strength design of the gear to allow for the use a Grade 1 steel. And it is intended for the reader to use his own experience in selecting formulae stress values etc. The word transmission is used for a device that is located between the clutch and the propeller shaft.

Design and Fabrication of Progressive Gearbox Report Download. This chapter begins with a comparison of the merits of spiral bevel gears and hypoid gears when employed as the final drive in the automotive gearbox ix. The purpose of this booklet is to set out the basic design for an industrial gearbox.

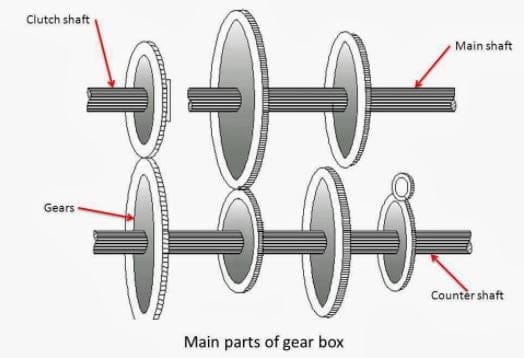

What Is Gearbox Types Parts Working Images Pdf

Sliding Mesh Gear Box Design Of Transmission Systems

Gearbox Definition Parts Or Construction Working Types In Detail Function Purpose Advantages Application Notes Pdf

Pdf Design And Static Analysis Of Automobile Gearbox Cover

Pdf Design And Static Analysis Of Automobile Gearbox Cover

0 comments

Post a Comment